GAMMA HIGH DISPLACEMENT SHOCK ABSORBERS

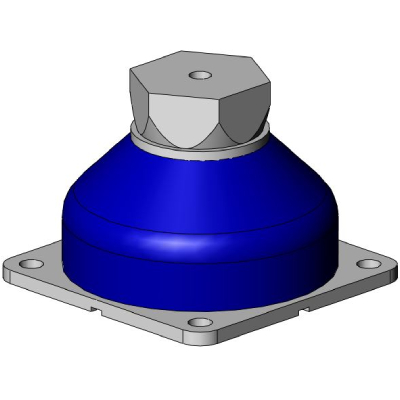

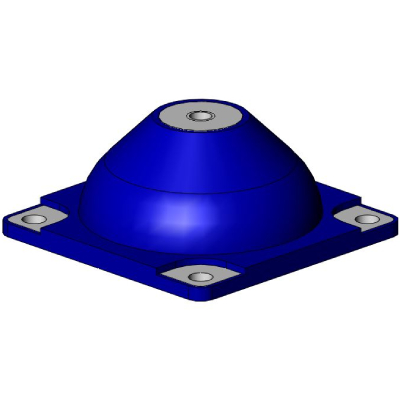

Often in the shape of a dome or cone, the technical characteristics of these shock absorbers cover a very wide range of loads, up to several hundred kilograms each, with vibration levels of up to +/-3 mm for frequency ranges from 6 Hz.

- Operating temperatures:-55° to 150 °C

- Filtration of very severe shocks or bumps of the order of 40 g/11 ms and 50 g/6 ms

- Vibration levels up to +/-3 mm

- Frequency from 6Hz

FIELDS OF APPLICATION

- Suspension of cabinets or racks

- Sensitive electronic equipment

- Inertial navigation systems

- Optical equipment

- Optronic aiming or pointing equipment

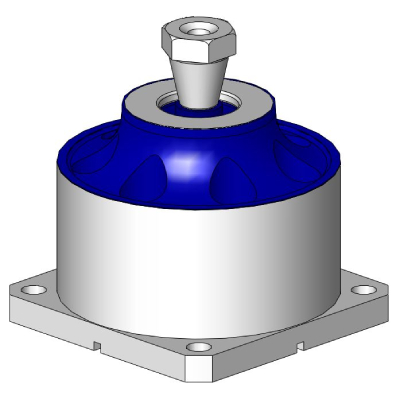

EXAMPLES OF HIGH DISPLACEMENT SHOCK ABSORBERS

These shock absorbers are also used to create insulations in fields more specific to navigation and optronic systems.

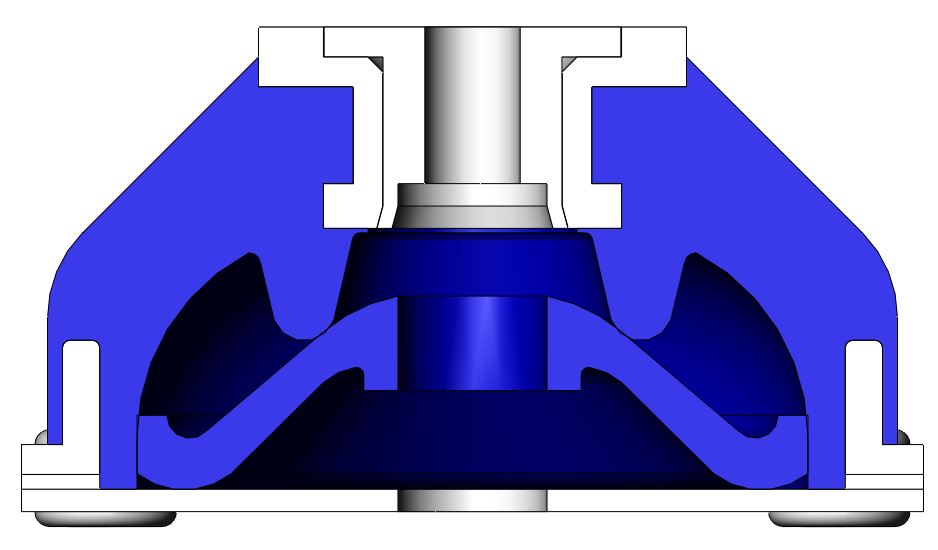

The principle behind these shock absorbers is to combine the intrinsic characteristics of our high-mechanical-performance elastomers with their ability to deform under stress.

This combination is used to achieve high working rates in relatively small volumes, effectively withstanding vibration levels of up to +/-3 mm with frequency ranges from 8 Hz and extended loading ranges. Another objective is to achieve high resistance to mechanical fatigue, with operational lifetimes of several million cycles, representing thousands of hours of operation.

GENERAL PRINCIPLES OF GAMMA HIGH DISPLACEMENT SHOCK ABSORBERS

These shock absorbers are ideally suited to high displacement capacity in a small footprint. They are also recommended for larger elements where very high elongation is essential for filtering very severe shocks or bumps of the order of 40 g/11 ms and 50 g/6 ms.

Their stiffness and damping characteristics are closely linked to the nature of the elastomer used.

Their design does not allow them to behave isotropically, as the stiffnesses in shear are lower than those in compression, which are themselves different from those in tension.

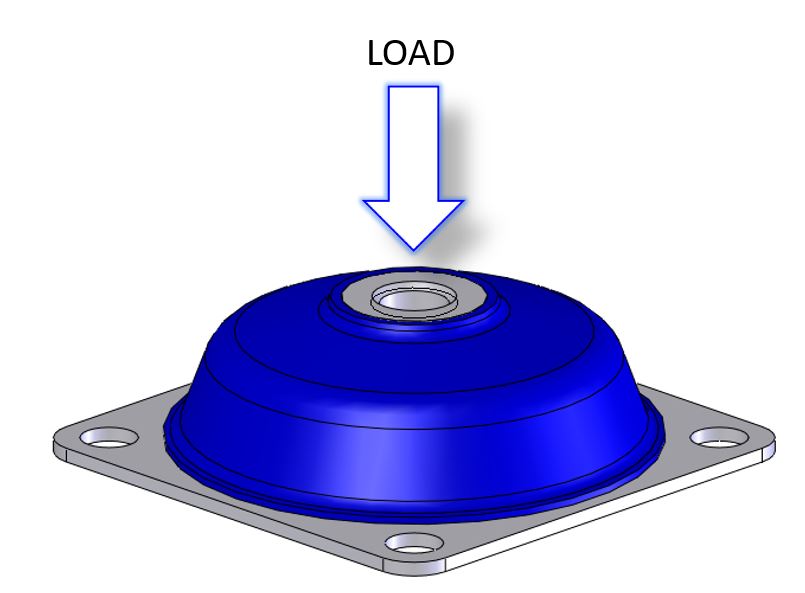

Another point to bear in mind is that the preferred loading of an elastomer is compression, which means that the preferred direction of assembly is in the vertical direction of compression in order to obtain the desired initial deformation.

A RANGE OF HIGH-DISPLACEMENT SHOCK ABSORBERS

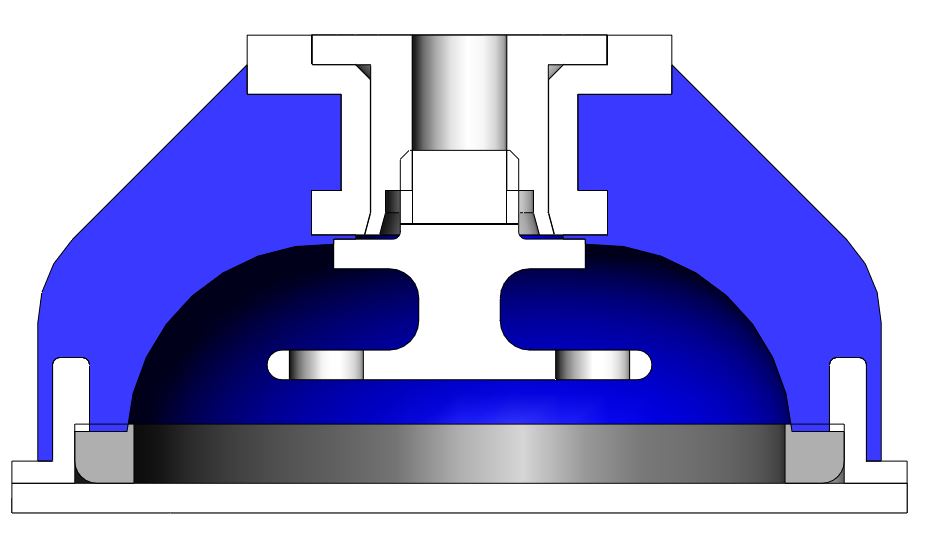

Compression mounting creates a deformation zone with no force recovery. However, depending on the circumstances, it may be necessary to compensate for this. This is why, in this case, the design of the shock absorber is adapted to incorporate a force recovery system using progressive stoppers that do not disrupt vibration behaviour but help to absorb energy in the event of an impact. The absorption capacity can be increased by adding an additional membrane component.

As with diaphragm shock absorbers, it is possible to obtain very high damping coefficients with elastomer-metal solutions by combining them with viscous damping. This combination has no effect on the operating temperature, which remains between -55°C and +150°C, as with the silicone versions.

Behaviour under shock is closely linked to the stiffness of the shock absorber. Please note: it is not always possible to optimise simultaneously anti-vibration and anti-shock characteristics.

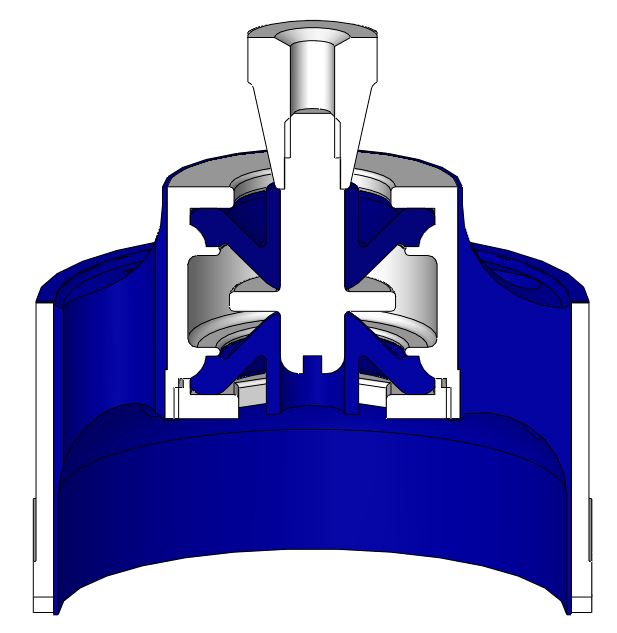

GAMMA’s engineers have therefore developed a very specific range in which it is possible to separate these 2 functions.

The central part, made up of 2 membranes, provides the vibration filtration function, often characterised by stress levels of the order of a few millimetres. In the event of an impact, requiring a greater capacity for movement, the first stage of the shock absorber comes into maximum compression and therefore into botoming, which causes the second stage, made up of an elastomer ring, to take up the forces and finish absorbing the residual energy linked to the impact.

This high-deflection shock absorber is particularly suited to marine environments where the 2 constraints (low vibration levels and severe shocks) coexist and need to be managed in an optimised way. As a result of this special construction, the characteristics become virtually isotropic again and loading can once more be carried out in all directions. This specific technology makes it unique in the family of high-displacement shock absorbers.

Do you have a project?

Don’t hesitate to discuss your project with us in complete confidentiality. We are ready to work with you to develop your ideal anti-vibration solution.