GAMMA BICONICAL AND RING SHAPE SHOCK ABSORBERS

GAMMA goes beyond the production of a standard range covering a wide range of applications. We develop biconical and ring shape shock absorbers based on specifications that meet the very specific needs of our customers, mainly in inertial navigation applications, geolocation such as laser guidance, optical or optronic sighting systems, not forgetting star pointer positioning.

To achieve this, our shock absorbers combine the intrinsic characteristics of our high mechanical added-value elastomers with designs developed and optimised by our experts in search of the best dynamic performance.

- Suitable for land, sea, space and air

- High reliability: less than 1% dispersion at resonant frequency, angular stability of a few milliradians

- Temperature resistance: -50°C to 150°C

- Resonance frequency from 25Hz

EXAMPLES OF APPLICATIONS

AS AN ALTERNATIVE TO STANDARD RANGES, CUTTING-EDGE EXPERTISE TO DEVELOP CUSTOMISED SHOCK ABSORBERS

The main objective of shock absorbers is to achieve isotropic performance under all loading conditions, with maximum damping or attenuation in specific frequency bands. As a result, our biconical and ring shape shock absorbers will provide excellent position feedback and angular stability throughout their long operational service life.

With compression and transfer moulding processes, GAMMA place particular attention to precision, reliability and reproducibility beyond commonly accepted standards.

To achieve these key objectives, we develop dedicated production tooling and manufacturing processes. For precise adjustment of dynamic characteristics down to less than 1% dispersion in resonance frequency with angular stability of a few milliradians, GAMMA adds particularly rigorous tuning phases.

SHOCK ABSORBER SIZING, A KEY PERFORMANCE FACTOR

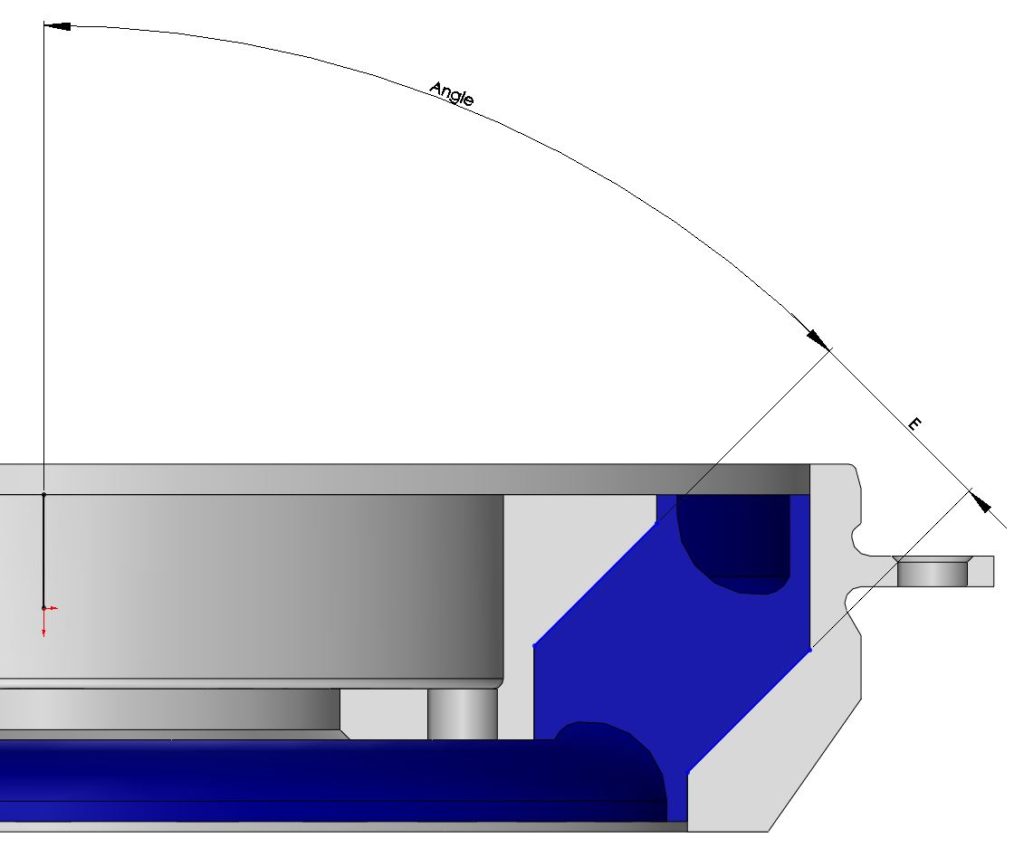

The basic principle is to absorb vibrations by means of elastomer segments carefully dimensioned using finite element modelling. This is how the thickness and angle are varied, so that they work continuously in compression, tension and shear.

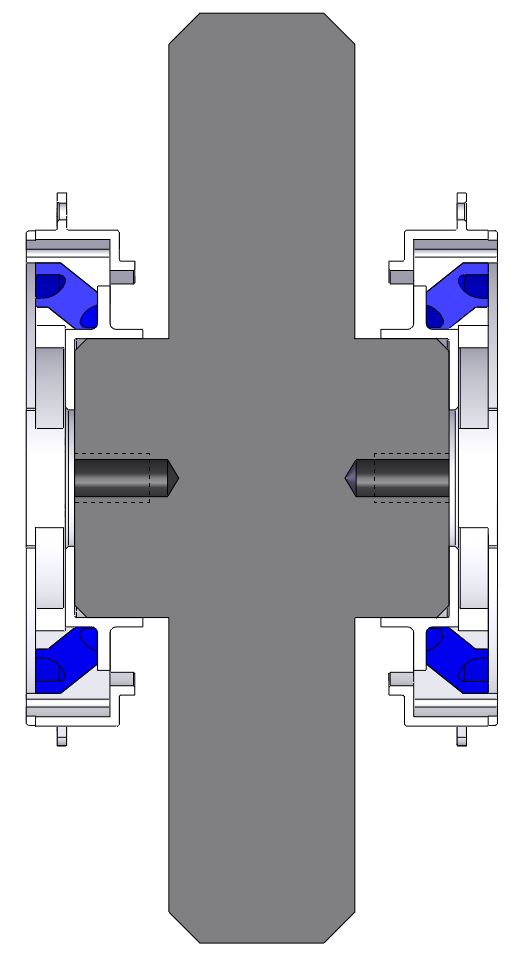

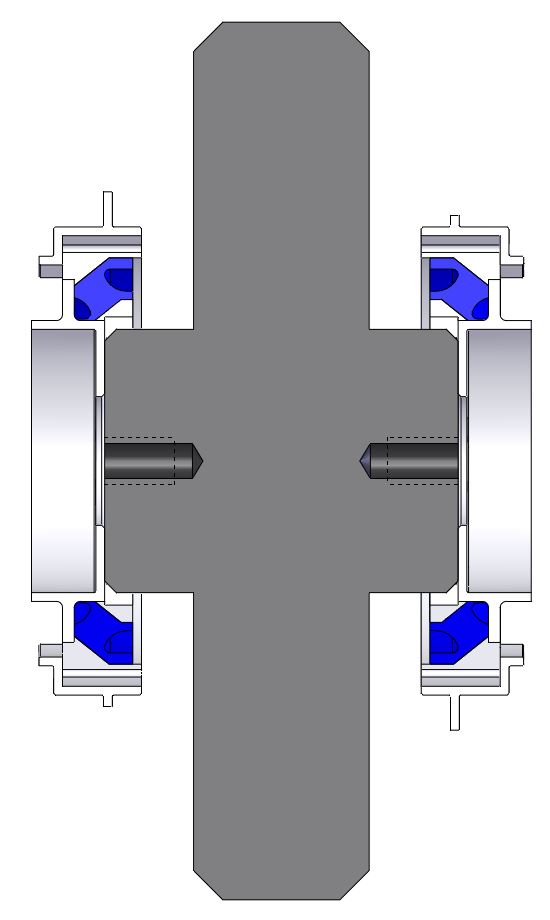

In the case of biconical products, GAMMA assembles 2 conical half-shock absorbers so as to always have an element working mainly in tension opposed to an element working mainly in compression. All this while taking care to perfectly size the free volume, the geometry of which determines:

- the ratio of axial stiffness to radial stiffness,

- the level of maximum displacement under load and the linearity of the behaviour.

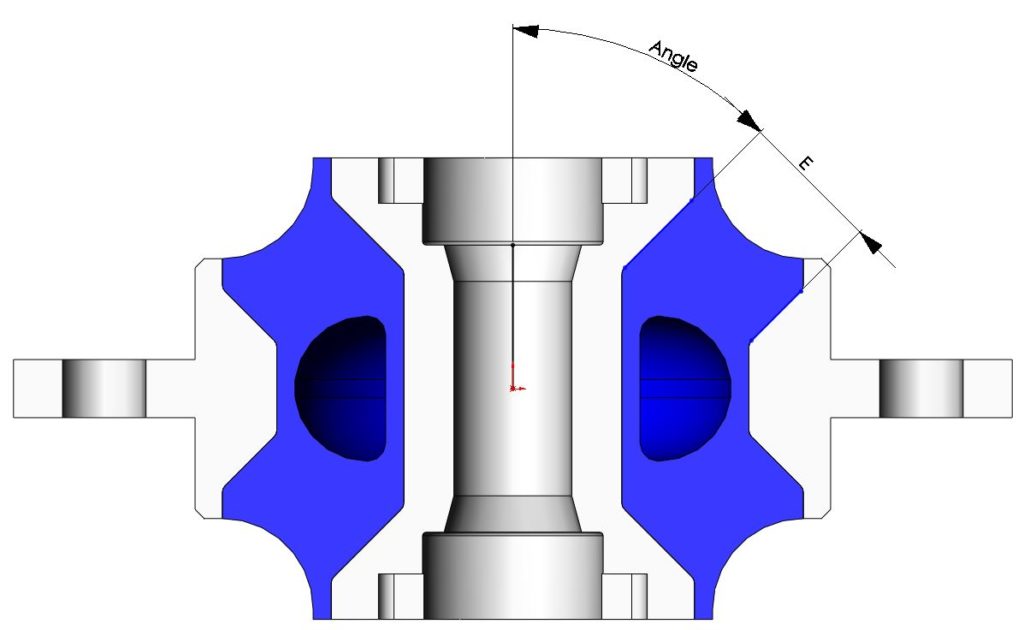

In the case of ring shape dampers, GAMMA generally implements 2 rings in opposition, in an “X” or “O” configuration. The choice of configuration type will be determined during the design phase based on:

- volume,

- of the mass to be suspended,

- stability performance.

In some cases, this stability will be achieved by combining a purely metallic element – to gain in dynamic stiffness – with elastomer segments to provide damping.

GAMMA OPTIMISES THE PERFORMANCE OF ITS SHOCK ABSORBERS

For biconical and ring shape shock absorbers, GAMMA adjusts their performance by varying the position angle of the elastomer segments.

For a wide range of applications, we develop the silicone anti-vibration element to cover a range of operating temperatures from -55°C to +150°C and resonance frequencies generally from 25 Hz up to a few hundred Hz. This design is perfectly suited to the presence of pyrotechnic shocks.

The layout of the shock absorbers opposite each other makes the suspension safe. In the event of rupture or complete destruction of the elastomer element, the suspended mass will remain attached to the structure to prevent any damage to equipment or people in the proximity.

Although the natural limits on displacement under load are obtained by sizing the segments to maximum compressibility values, GAMMA can combine its biconical and ring shock absorbers with soft-stop systems in all or some directions. These systems can be integrated or added separately.

Do you have a project?

Don’t hesitate to discuss your project with us in complete confidentiality. We are ready to work with you to develop your ideal anti-vibration solution.